Condition Monitoring

Condition Monitoring Services

How efficient is the operation of your machines? How long do they actually operate during a shift? How long does their changeover or fault removal take?

These are critical questions for any industrial setup, as unexpected downtime can significantly impact productivity and profitability.

Whether it is conveyor belts, industrial robots, hydraulic units, motors, pumps, or air systems, the failure of individual components in complex plants can lead to a complete shutdown of the facility. To prevent this, continuous monitoring of key components is essential.

Importance of Condition Monitoring

At each component level, various indicators can be used to assess the condition of your machinery. One of the most effective methods is vibration monitoring, which is crucial for rotating machines, systems, and individual parts. Vibrations are an early warning sign of wear and tear, which, if ignored, can lead to severe damage and failure. Similarly, temperature monitoring plays a vital role in ensuring the proper function of machines. Sensors can be placed to measure the contact temperature of critical components such as spindles, bearings, motors, and even fluid systems.

Beyond vibration and temperature, additional indicators such as pressure levels, acoustic emissions, and lubrication quality can also be tracked to detect anomalies before they result in costly breakdowns.

Advanced Data Integration for Smarter Decision-Making

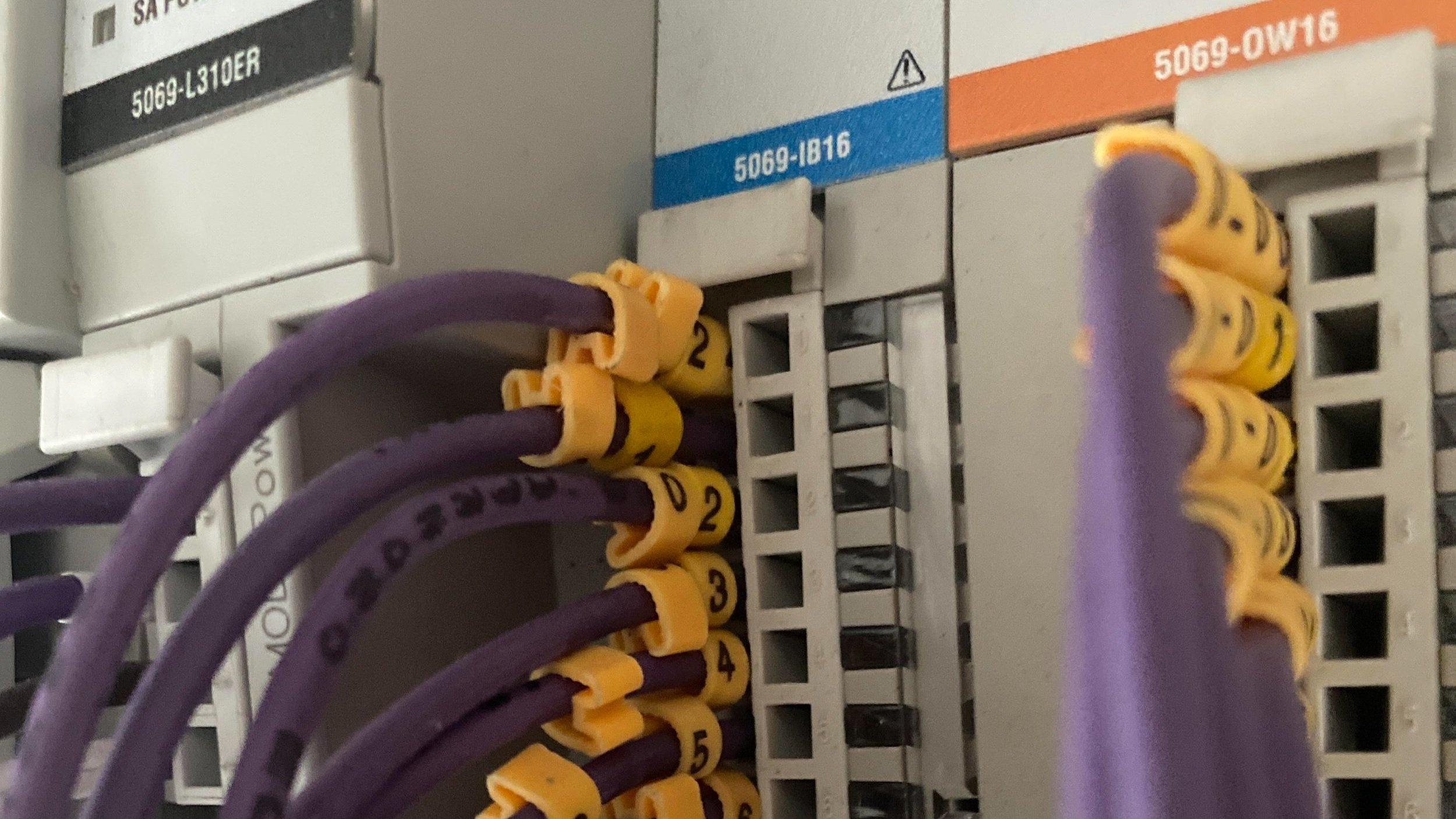

The indicator information gathered by these sensors must be efficiently communicated to control systems, supervisory platforms, or the cloud. With real-time visualisation and remote diagnostics, operators can detect potential issues early, plan predictive maintenance, and optimise machine performance. This proactive approach reduces downtime, extends equipment lifespan, and enhances overall operational efficiency.

Condition Monitoring Services in New Zealand

ACSE specialises in Condition Monitoring Services in New Zealand, providing tailored solutions for industrial automation systems. From simple standardised condition monitoring setups to highly customised complex system integrations, we offer cutting-edge solutions to keep your machinery running at peak efficiency. Our monitoring technology helps businesses across industries detect faults before they escalate, reduce maintenance costs, and improve system reliability.

Investing in a reliable condition monitoring system is not just about preventing failures—it’s about ensuring seamless operations, boosting productivity, and staying ahead in the ever-evolving industrial landscape. Let ACSE help you take your machine performance to the next level. Contact us today to learn more about how our Condition Monitoring Services in New Zealand can benefit your business.