Automated Change Over System

Change Over System

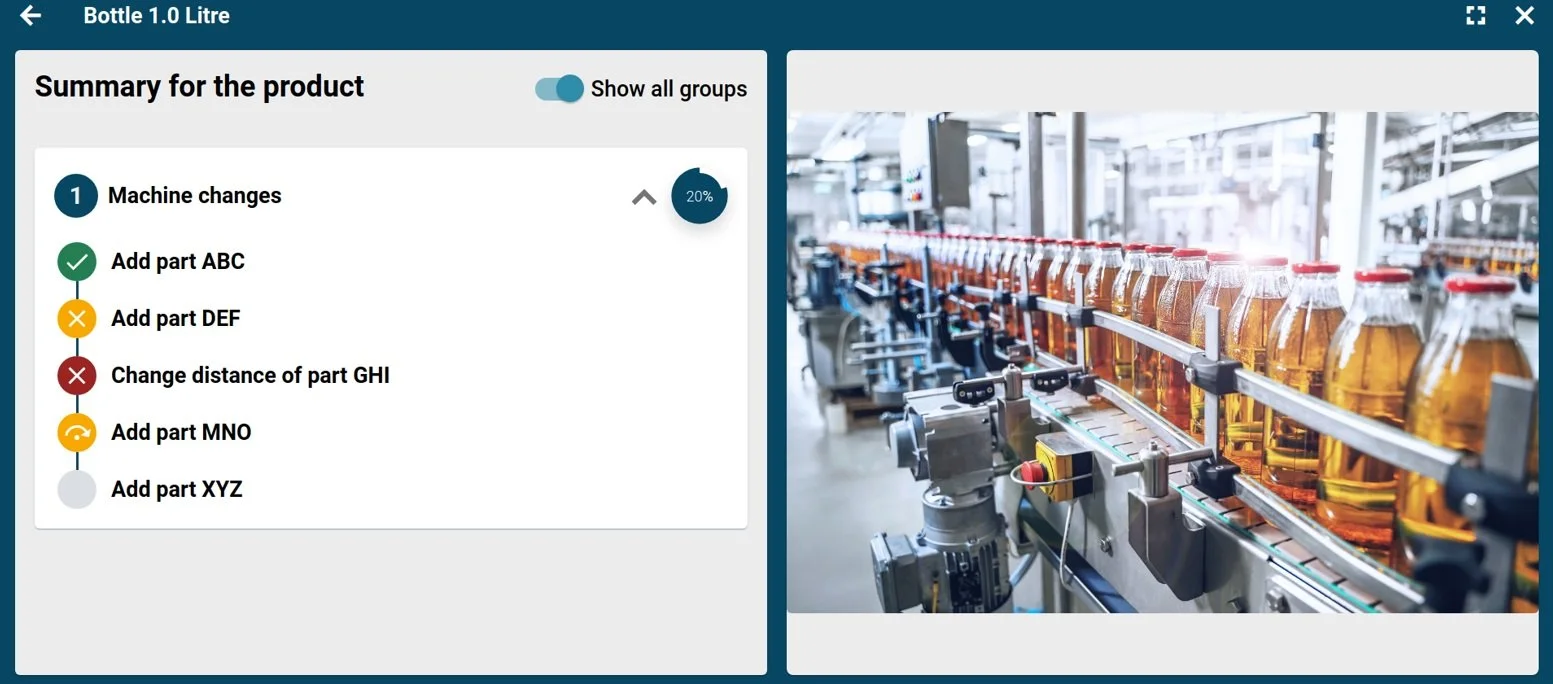

Production comes with many challenges. One very significant and recurring problem is downtime and the related challenge of reducing it. At ACSE, we understand that manufacturers are constantly looking for ways to increase efficiency, reduce waste, and optimise their operations. Our Automated Change Over Systems in NZ provide a smart solution to streamline production processes, improve flexibility, and maximise productivity.

Enhancing Production Efficiency with ACSE Change Over Systems

Our Change Over Systems in NZ are designed to enhance Overall Equipment Effectiveness (OEE) by partially automating the changeover process of machines. By doing so, businesses can reduce scrap production, minimise downtime, and shorten the duration of format changeovers. This results in increased plant availability and a more efficient production flow.

How Do We Do It?

Just three simple steps lead to a noticeable increase in plant availability and OEE - Overall Equipment Effectiveness:

1. Automated Guidance for Changeover – Our system provides operators with step-by-step instructions, ensuring accuracy and reducing human error during the changeover process.

2. Real-time Monitoring and Feedback – Operators receive real-time data on the progress of the changeover, allowing them to make necessary adjustments and avoid production delays.

3. Seamless Integration with Existing Systems – Our solution can be integrated into your existing production setup, ensuring a smooth transition without major disruptions.

Why Choose ACSE Change Over Systems in NZ?

Our Guided Change Over Solution is adaptable across various industries and is particularly suited to the stringent requirements of the food, beverage, cosmetics, pharmaceutical, and packaging sectors. Our system is ideal for businesses that:

● Frequently switch between small batch sizes, requiring frequent machine and line adjustments.

● Have multiple changeover points, making the transition between production runs time-consuming.

● Rely on well-trained and experienced employees for manual changeover procedures.

● Operate production lines with several machines that need simultaneous adjustments.

● Experience prolonged start-up times after changeovers, leading to high material waste and inefficiency.

Key Benefits of ACSE Change Over Systems in NZ

● Significant Reduction in Downtime – Minimise production interruptions and improve efficiency.

● Lower Scrap and Material Waste – Reduce errors and material loss during the transition between production runs.

● Optimised Workforce Utilisation – Reduce dependency on highly experienced personnel for changeover tasks.

● Improved Consistency and Accuracy – Achieve precision and reliability across all changeover processes.

● Enhanced OEE (Overall Equipment Effectiveness) – Boost productivity and plant availability with streamlined operations.

Future-Proof Your Production with ACSE

At ACSE, we are committed to providing cutting-edge automation solutions that enhance productivity and efficiency for manufacturers. Our Change Over Systems in NZ are built to handle the challenges of modern manufacturing, ensuring faster transitions, reduced downtime, and increased profitability.

Investing in an Automated ChangeOver System means investing in the future of your production. Contact us today to learn how ACSE can help optimise your production line and take your manufacturing efficiency to the next level!