Food Industry

Automation in the Food Industry

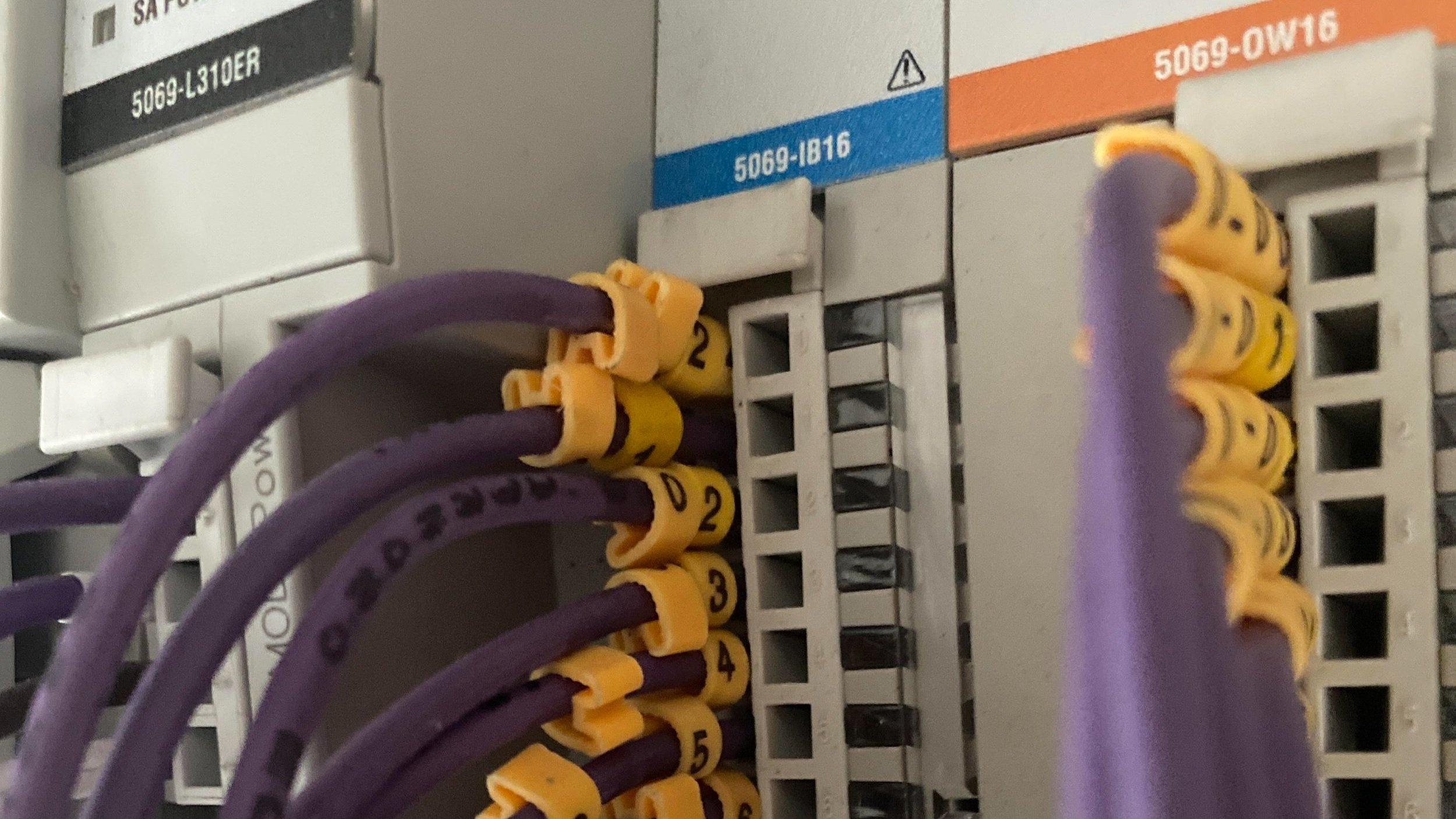

ACSE Ltd specialises in delivering cutting-edge automation services customised for the food industry in New Zealand. Committed to pushing the boundaries of innovation and efficiency, ACSE Ltd revolutionises manufacturing workflows, boosting output while upholding the utmost levels of food safety and quality. Their skilled group leverages the most recent technological breakthroughs to create and deploy customised automation systems that simplify processes and increase earnings for food producers in Auckland and Hamilton. Whether it's improving production lines or incorporating sophisticated robotics, ACSE Ltd guarantees that each solution is tailored to the specific requirements of our customers, establishing new standards in the field. ACSE Limited is a leading provider in designing Electrical and Automation Systems tailored for the food industry, enhancing efficiency and precision in production processes across Auckland and Hamilton.

Bulk Material Handling and Recipe Batching Plant: ACSE Limited engineered the Electrical and Automation Systems for a sophisticated bulk material handling and recipe batching plant. Beginning with detailed P&ID schematics, our team orchestrated the seamless flow of flour, sugar, and by-products from bulk bag off-loaders to a blending unit. Operators effortlessly select recipes via intuitive touch screen panels, ensuring precise weighing and batching of ingredients. Mixed products are seamlessly transferred to a high-speed packing line, where final retail packaging occurs.

Our scope included designing the electrical installation, integrating a robust main MCC with PLC controllers, and deploying ergonomic operator stations equipped with touch screens. These touch screens serve dual roles, facilitating recipe selection and overseeing critical plant operations such as Clean In Place (CIP) protocols and overall plant control.

Bulk Sugar Handling System - AB Foods, New Zealand: For AB Foods in New Zealand, ACSE Limited engineered a tailored Electrical and Automation System for bulk sugar handling. Our PLC controller program efficiently conveys sugar from large storage tanks to smaller holding hoppers, optimising operational throughput. A user-friendly SCADA control system allows operators to monitor and manage processes via touch screen interfaces, ensuring seamless operation with minimal downtime. The touch screens also support essential functions like Clean In Place (CIP), maintaining stringent hygiene standards.

Crumb Handling Plant - Sara Lee, Australia: ACSE Limited extended its expertise to Sara Lee in Australia, designing an Electrical and Automation System for a specialised crumb handling plant. Beginning with the unloading of crumbs from bulk bag off-loaders, our solution efficiently conveys the product to dedicated hoppers for further processing. These hoppers seamlessly integrate into the production line, where crumbs are transformed into the base for delicious cakes. The system is overseen and controlled via intuitive touch screen interfaces, empowering operators to manage operations effectively while adhering to stringent quality standards.

For comprehensive automation in the food industry in New Zealand, ACSE Limited stands ready to innovate and optimise your production processes. Contact us today to discover how we can elevate your operations with cutting-edge Electrical and Automation Systems.